Fuzzy Logic Controllers

Fuzzy Logic Controllers

Fuzzy Logic – an Introduction

Boolean logic, commonly used in automatic control systems, is described through a bivalent lens, being either true or false. Nevertheless, the binary viewpoint cannot adequately describe vague or ambivalent scenarios. For example, one must set a strict boundary when using boolean logic to label people according to their height. Using 1.80m as the boundary between “tall” and “non tall” means that someone whose height is 1.79m is “non tall” and someone whose height is 1.81m is “tall”. However, describing people as “tall” is subjective, depending on personal preferences and comparisons. In these cases, the ambiguity of the language is best represented and analyzed by fuzzy logic.

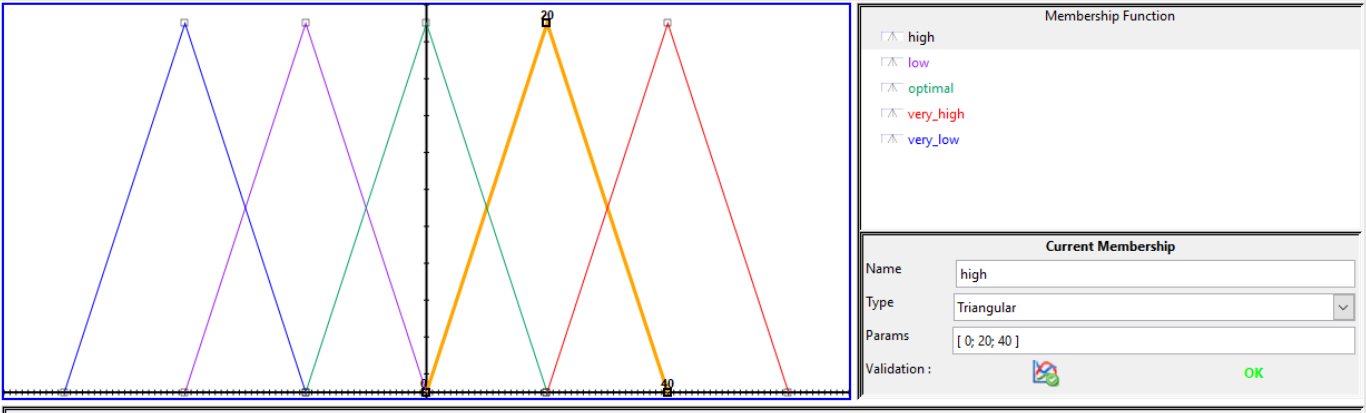

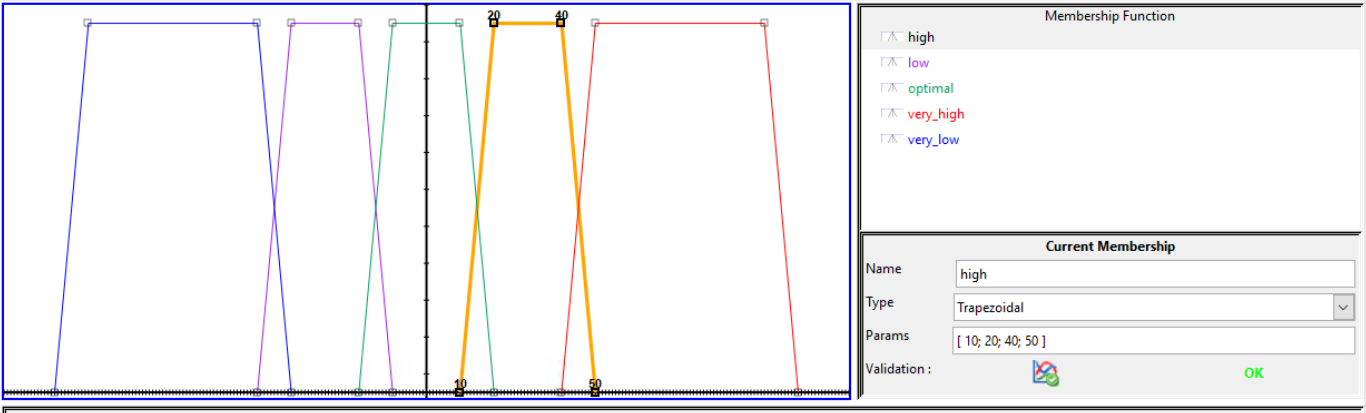

Unlike boolean logic, fuzzy logic distributes the elements in fuzzy sets (sets with overlapping boundaries). The characteristic function, which describes an element’s degree of membership to a set, can take any value in the interval [0;1]. Thus, a given element can belong fully (value 1), not belong (value 0), or partially belong to a given set (value in the range ]0; 1[). Additionally, any particular domain element can belong to several sets with varying degrees of membership. The characteristic function can have different shapes, the most common being triangular, trapezoidal, or Gaussian.

Fuzzy Logic Controllers

A fuzzy controller is the practical application of fuzzy logic on a control system, being most useful in cases where obtaining a mathematical model or non-linear systems is difficult. It describes the control protocol through IF-THEN rules, having the potential for classification, decision and control applications that mimic human thinking.

A fuzzy controller has four main pillars:

- The rule base holds knowledge about how to best react to a given scenario;

- The inference engine evaluates the scenario and chooses the applicable control rules;

- The fuzzification interface translates the input variables into elements that can fit into the rules in the rule base;

- The defuzzification interface translates the inference results into information the plant can use as input.

Within the fuzzy controller cycle, several process variables are read from different sensors across the plant and used to perform calculations. The calculations allow the determination of the correct decision to maintain system stability while maximizing production and/or decreasing energy consumption and emissions. The decision is then sent to plant equipment control, similarly to human operators.

According to the fuzzy control methodology, the fuzzy control system is based on human rules. Process engineers easily understand the rules introduced, not requiring any control specialist to maintain the system.

Practical Applications

As an example of a fuzzy control system, we can have a kiln that consumes a mix of fuels. The kiln’s temperature is closely monitored; the amount of provided fuel is manipulated according to it. The temperature can be sorted into the fuzzy sets according to the distance to a specified setpoint: very low, low, optimal, high and very high. Each set has a corresponding characteristic function, here represented as a triangular function (figure 1) and a trapezoidal function shape (figure 2). The type of characteristic function is chosen according to the context.

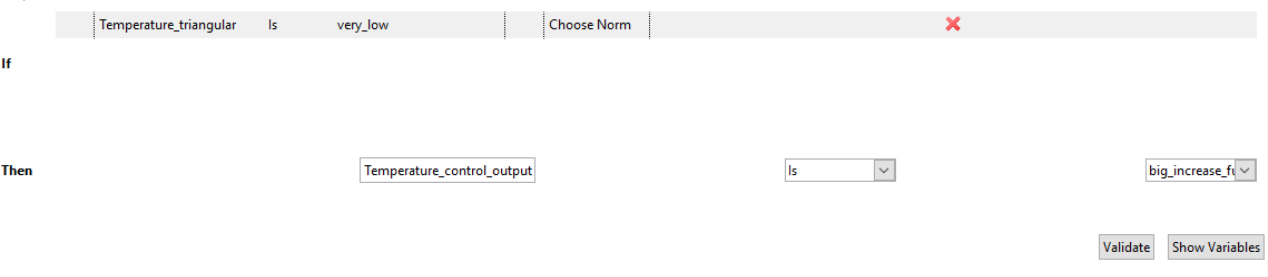

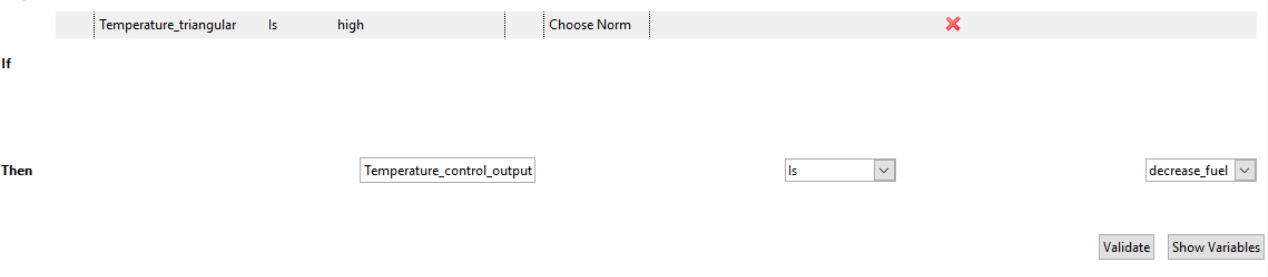

Kiln temperature is measured in real-time, and for each input, the system determines the temperature value’s degree of membership to each fuzzy set and calculates a value for the output, according to the defined rules (see examples in figures 3 and 4).

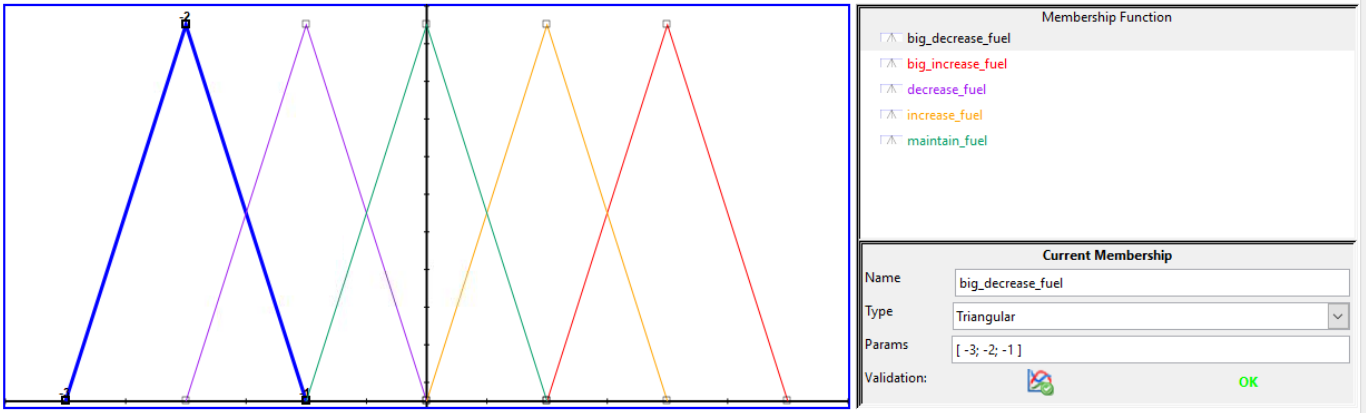

The output value will have a degree of membership in the defined output fuzzy sets (figure 5). The resulting conclusion will set the optimal amount of fuel pumped into the kiln. The value is transmitted to the plant equipment control equipment and actuated on plant actuators.

Oncontrol provides advanced solutions for process control using Fuzzy Logic. When the system is installed, the plant personnel discuss the desired system behavior and the available variables with Oncontrol engineers. These variables are read on the software, and a rule base database is created, considering the required membership functions to characterize the variables. The system is then ready to operate in automatic mode, and plant personnel can ask for changes or adaptations at any time. The software’s structure allows for agile and quick control logic changes.

The Oncontrol software has been tested worldwide in cement and combustion processes, with recognized improvement in installed processes.

Author

Leonor Marques