Industrial symbiosis

Industrial symbiosis

Introduction

The industrial revolution triggered a new mindset in manufacturing organizations, leading to having as primary objectives linked to the increase of economic profit and resource throughput. The industrial revolution ideology is identified by a linear model, where raw materials are extracted, transformed into products, commercialized, and finally discharged to landfills.

[Gar+19] argues that the linear business model represents an unsustainable approach to manufacturing and consumption of goods since it can lead to scarcity and:

- Permanent damage of natural and non-renewable resources;

- Pollution of soil and water;

- Increased greenhouse effect gases emissions.

The author argues, “Therefore, the search for alternatives started, and the circular model increasingly drew more attention. This model advocates a closed loop, a circular flow of materials, raw materials, and energy in the entire economic system, keeping resources in the economy for as long as possible.” [Gar+19]. The referenced article describes the principles of the circular economy.

Industrial symbiosis is an example of the application of the circular production model. It is part of the emerging field of industrial ecology and engages industries that are traditionally separated in a collective approach [Che00], where wastes or by-products of an industry or industrial process become the raw materials for another [Com18].

In the PRODUTECH4S&C project, the focus turns to the recovery of thermal energy, which nowadays is mainly dependent on fossil fuels. The main goal is to decrease the global level of decarbonization and increase energy optimization for industrial ecosystems.

Types of Symbiosis

Symbiosis for industrial thermal usage can be classified into two categories:

- Intra-industrial: the re-utilization of heat is done inside the own industrial layout of the manufacturing organization.

- Inter-industrial: the re-utilization is done through a heat network to distribute the heat through different consumers.[Jos22]

This article will discuss only inter-symbiosis and some notions on the calculus to create a symbiosis network.

Inter-industrial Symbiosis

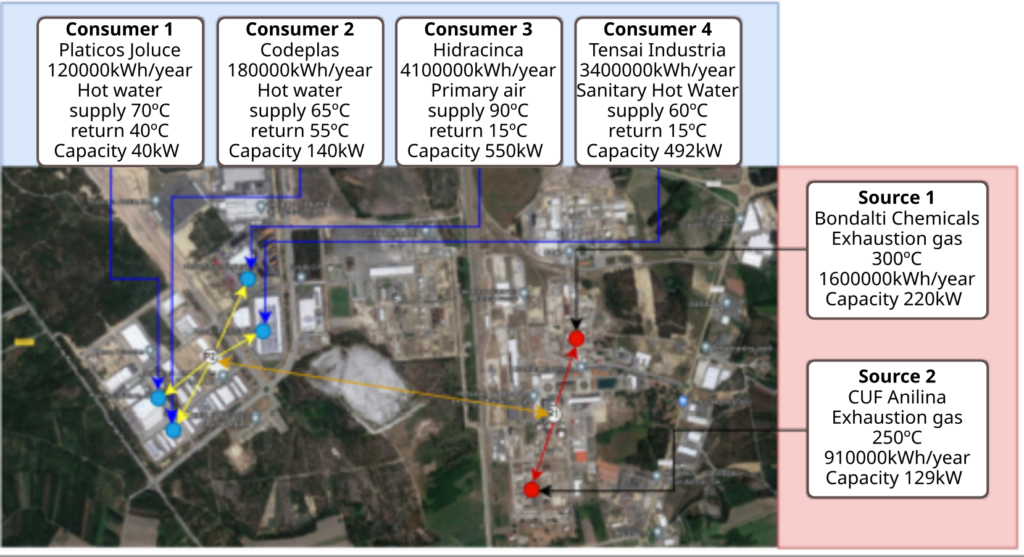

To validate possible symbiotic relationships, it is necessary to analyze potential heat producers and consumers in restricted neighborhoods and characterize:

- Thermal powers;

- Temperature intervals;

- Heat exchanger(s) for each site in the network.

These characteristics will allow calculating the costs of a symbiosis relationship between different enterprises/sites.

The heat transfer equipment was used to validate the economic analysis of the heat network. Heat exchangers are the most used equipment to transfer heat between hot fluid fluxes. The choice of the heat exchanger has to be made considering which fluids are used. Commonly used pieces of equipment in industrial companies are plate-heat exchangers, shell and tube heat exchangers, and economizers. [Jos22]

Calculus of site conversion

In each consumer site, it is necessary to calculate the heat exchanger to be used with the circulation group.

The circulation group is the set of circulation pumps that allow the circulation of the heat transfer fluid. To know the pumping costs, the appropriate fluid flow for the required power consumption is calculated.

The conventionally used heat exchangers in heat networks are plate-heat exchangers. To get adequate plate-heat exchangers, it is necessary to know the required area of the plates. [Jos22]

Calculus for the usage of residual heat

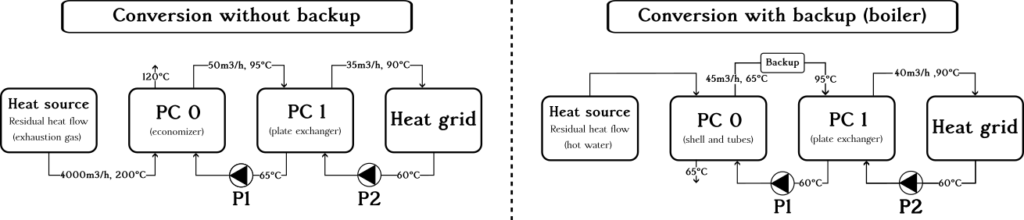

The conversion of fluxes of residual heat in a production company available for a heat network requires the installation of an intern network (intermediate circuit) to recover the residual heat flux and deliver it to a heat network. The fluid used in the intermediate circuit is chosen based on the temperature of the flux of residual heat. Depending on this temperature and the consumer’s needs, the conversion may need a backup to fulfill the temperature requirements.

The calculus of the needed heat exchangers is similar to the previously resumed process. It is also necessary to obtain the backup power used, if necessary. [Jos22]

Calculus of the heat network

To find the best heat network, the costs of each combination of sources and consumers must be determined by calculating the length of the several sections of the heat network for each option. The annual energy exchange for each combination must also be calculated, along with other parameters, allowing the calculation of combinations to which the energy cost is lower. [Jos22]

Developed Solution

Oncontrol is creating a platform for engineers to assess the possible symbiosis between enterprises, where the costs and other economic variables are calculated for the several combinations introduced in the platform. This will allow better planning of new symbiosis clusters.

A description of Oncontrol’s heat symbioses solution will be described in a future article.

References

[Che00] Marian R Chertow. “Industrial symbiosis: literature and taxonomy”. In: Annual review of energy and the environment 25.1 (2000), pp. 313–337.

[Com18] European Commission. Industrial Symbiosis. Accessed on March 20, 2023. 2018. URL: https://ec.europa.eu/environment/europeangreencapital/wp-content/uploads/2018/05/Industrial_Symbiosis.pdf .

[Gar+19] Jose Arturo Garza-Reyes et al. “From linear to circular manufacturing business models”. In: Journal of Manufacturing Technology Management 30.3 (2019), pp. 554–560.

[Jos22] Bruno Pereira José Maria Cunha André Lisboa. Modelos de valorização energética via simbiose industrial. INEGI, 2022.

[Cir] Circulérie. What is the Circular Economy? Accessed on March 21, 2023. URL: https://circuleire.ie/the-circular-economy/#what-is-the-ce .

Author

Maria Moita