Industrial Symbiosis – Developed Solution

Industrial Symbiosis – Developed Solution

Introduction

Industrial Symbiosis is the application of the circular production model in which materials, raw materials, and energy flow in a closed loop, keeping resources in the economy for as long as possible. There are two types of industrial symbiosis: inter- and intra-industrial. In this article, we will focus on inter-industrial symbiosis, specifically regarding thermal energy. More information about industrial symbiosis is available in the previous blog post here.

In simple terms, inter-industrial thermal symbiosis is the re-utilization of thermal energy through a heat network to distribute the heat through different consumers. Thermal energy is mainly dependent on fossil fuels, therefore the recovery of residual heat leads to a path of decarbonization and energy optimization for industrial ecosystems.

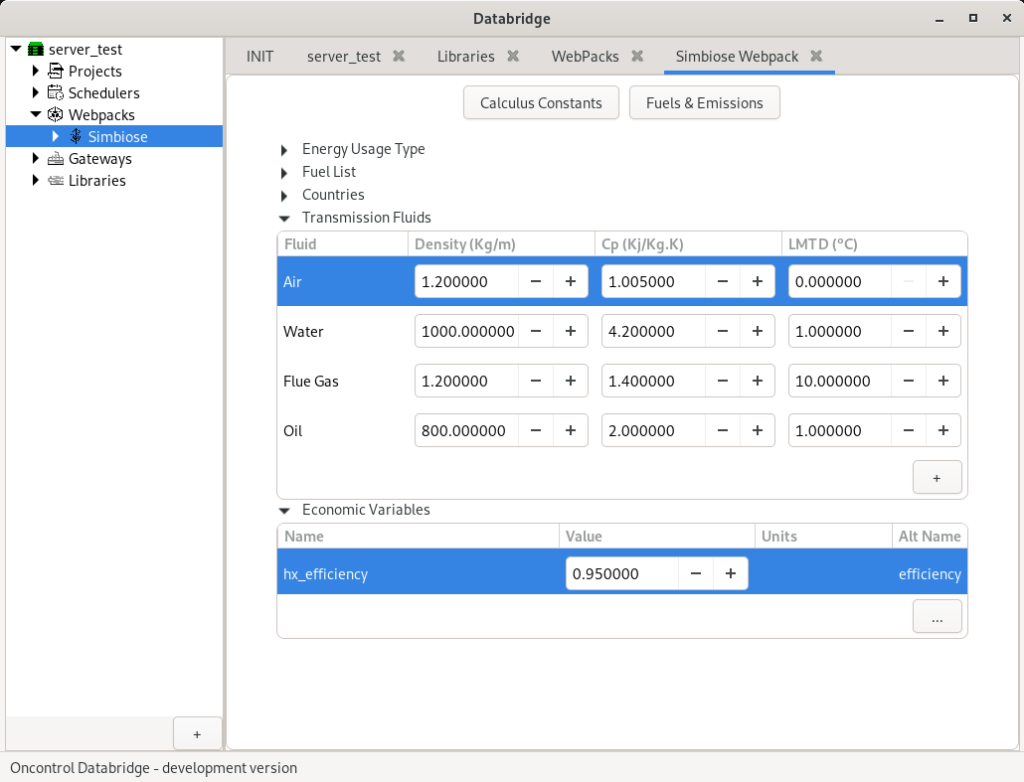

In the context of the PRODUTECH4S&C project, Oncontrol has developed an Industrial Symbiosis solution for inter-industrial thermal symbiosis. This tool, which is implemented on databridge, allows the user to assess possible heat networks between enterprises. First, the calculus constants must be inserted into the system through databridge CT (Configuration Terminal), and then the final user will access the data on databridge Web.

Calculus Constants

The developed algorithm uses some constant values, which the engineering personnel input into databridge CT. These values include:

- a list of countries where the heat network is meant to be designed;

- different types of fuel, their emissions, and prices (according to each country);

- different types of energy use (Industrial/Domestic/Other);

- types of transmission fluid (and the respective physical properties);

- economic variables (which were determined in the development of the algorithm).

Once these values have been inserted, the solution is ready for the user to explore.

The heat network

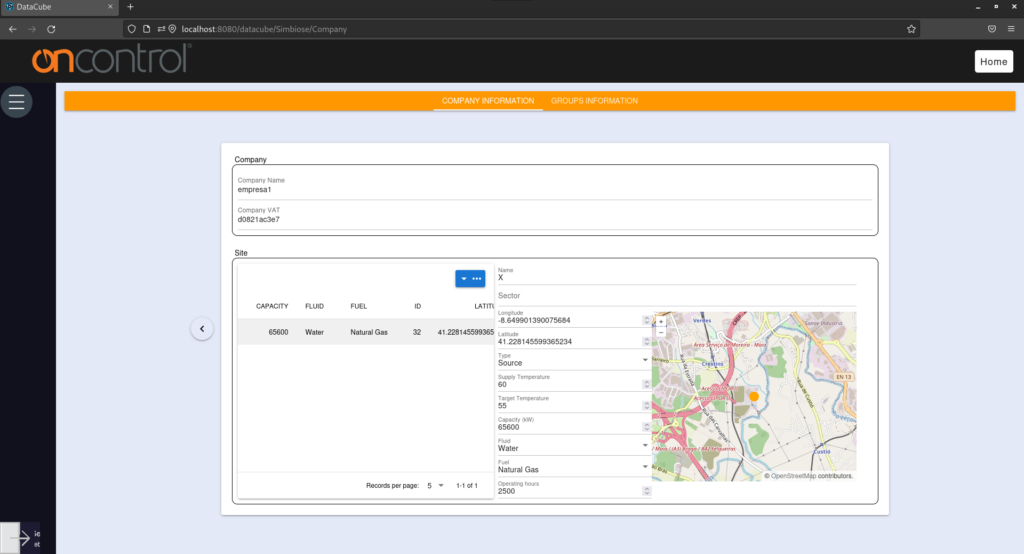

The final user interface is where the user inserts the information they already know, such as the different enterprises that integrate the heat network and their properties. The user will then create groups (combinations of enterprise sites) for which they receive the final results.

The company information to be inserted includes:

- GPS coordinates;

- role in the heat network (source/snk);

- operating hours (hours/year);

- capacity (kW) (energy the site can transfer to the heat network);

- supply temperature (ºC);

- target temperature (ºC);

- fuel used in the site’s heating system;

- transmission fluid (fluid meant to be heated/cooled).

With each company having a complete profile inserted into the system, the user may then assess different hypothetical heat networks by creating groups with different combinations of companies. Each group must include at least one “source” and one “sink” to be considered complete. Additionally, a group also requires the following information:

- country;

- user type;

- supply temperature (temperature of the heat network fluid after being heated by the source);

- return temperature (temperature of the heat network fluid after heating the sinks and before being heated by the source).

Final results

Oncontrol’s solution for inter-industrial thermic symbiosis considers the group’s information and presents the user with a page detailing the hypothetical heat network connected to the selected companies. The provided information includes (but is not limited to):

- overall investment costs (€);

- grid capacity (kW);

- energy exchanged (MWh);

- grid investment for each enterprise in the group (€);

- payback time (years);

- overall decarbonization (tonCO2/year).

The information presented in the final report enables the user to analyze different groups, find the most optimized heat network, and quickly estimate the viability of such an investment.